Sublimation printing is a beneficial and profitable business. With customized printing for personal items, its market has experienced a boom in the last couple of years. Here we will understand how dye-sublimation printing works and how to make money out of it. But first thing first.

What is Sublimation Printing?

Technically, sublimation is the process of converting solids into a gaseous state. Sublimation printing is a method to transfer the printed designs to the sublimation-compatible substrate, polyester-coated ceramics, or fabrics, using pressure and heat (Standard between 180°C/356°F to 190°C/374°F)*.

As the process of transferring the printed design to the substrate is so easy small companies and people at home are inclined toward this method.

*Important: The settings may vary depending on your transfer equipment and substrate.

The Printing Process

As we learned that the sublimation printing process is way easier than other types of printing processes and allows customization as per personal needs. When it comes to producing a printed pattern, one must consider the following:

- A Computer/Desktop (including RIP Software for large-scale production)

- A 4-color or 6-color Sublimation Printer (Epson L3110 / Epson L805 — Recommended for micro-scale business)

- Sublimation Ink for Epson Ecotank Printer (use inks as per your printer model)

- Sublimation Paper

- Finished Design

- Sublimation Compatible Substrate

- Heat Press / Vice (depending on the type of substrate)

Once you gather all the mentioned things ready, all you got to do is follow to perform the process. We will not take a lot of your time explaining the process, instead, we have created a short video on how you can quickly transfer the prints to the substrate. Do check it out.

People Also Ask

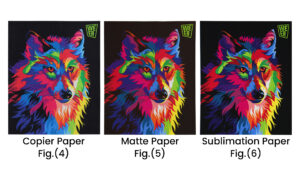

1. Can we use copy paper or matte paper to reduce printing costs?

We strongly recommend using good-quality Sublimation papers for high-quality transfers.

Sublimation paper’s special coating ensures the release maximum amount of ink by holding the print onto the surface.

Since plain copier papers or matte papers, don’t have this type of coating, the quality of the transfer print is poor.

2. Why my prints are not as sharp as in the design?

Sublimation transfers are known for high sharpness. There can be many possibilities if you are not getting sharp transfers.

- Poor Image Quality

When you print low-resolution images, the print & ultimately the transfer may not be of the desired sharpness.

- Improper Print Settings

If the print settings result in excess ink on paper, it may result in a loss of sharpness. This happens mainly with the slow-drying sublimation papers.

- Improper Transfer Equipment

The heat press is not able to maintain the proper pressure across the transfer area. This results in a loss of sharpness.

- Inadequate Transfer Settings

The sublimation dye migrates to adjoining areas if you use excess temperature or time during the transfer process. This results in poor transfer results.

- Improper Quality of Substrate

This happens when you use improperly coated sublimation transfer items.

3. Why my designs are washed-out or ghosted?

The chances you get a washed-out or ghost design are due to improper heating and applied pressure even though you got the perfect paper, perfect design, and even the sublimation-compatible substrate. Heat and pressure play important roles in sublimation printing.

- Washed-out Design — Improper Heating

If you perform the transfer for a longer time or exceed the temperature then the required results in washed-out colors.

- Ghosting Design — Inadequate Pressure

This happens when during transfer there’s the movement of paper, resulting in a ghosting phenomenon.

How to make money using Sublimation Printing?

There are two types of sublimation businesses that you can go for i.e. Print & Stitch (includes Textile Sublimation printing and stitching for large-scale companies), and Print & Press (includes Stitched garment/sublimation substrate printing for small-scale businesses).

The print & press sublimation business is much more reliable and profitable for small-business owners to make a few quick bucks. Nowadays customized printing is gaining the market and the cost of producing an HQ sublimation T-shirt ranges from $7 to $10 (may change depending upon substrate and operation cost). Not only T-shirts but you can also use sublimation printing to print on any other polyester or polyester blend substrates.

Market research and its influence play an important role when it comes to profit margins. We strongly recommend you do thorough market research before setting up your profit margins.

Conclusion

Sublimation printing is a fantastic option when it comes to producing full-color, high-quality images for clothes and other items. Since there is barely any downtime, all the products are profitable (if you are selling them to clients) and you can produce as much as you like.

It is one of the most affordable printing methods accessible since, if you already own a computer, you can invest in a sublimation printer that connects wirelessly and only has to buy transfer paper and ink for printing.

When considering commencing sublimation printing, keep in mind that the heat press will be the most expensive aspect of the process.