Digital Textile Pigment Ink is seeing increased adoption by the textile industry. Improved reliability, color performance, and versatility with the fabrics that can be printed are the key drivers of growth.

In addition, digital textile pigment inks present themselves as one of the least water-consuming fabric printing techniques. This makes printing with Digital Textile Pigment Inks a truly Greenway of printing on fabrics.

Just like all other digital textile print processes, pre-treatments play a very crucial role when using digital textile pigment inks. However, unlike another process where pretreatment is necessary for fixation of the inks, the role of pretreatments for pigment inks is limited to improving the performance of the printed fabrics. Let’s understand more about this.

Let’s start with the basics of fabric preparation first. “PFP” or “Prepared for Print” fabrics generally are processed to remove various oils, waxes, sizing agents, etc used during various stages of manufacturing. These chemicals interact and prevent proper fixation of the inks. Removal of all these unwanted chemicals is essential to have reliable color and fixation performance of the inks.

In addition to the process chemicals, it’s important to remove the “lint” or “protruding fibers” from the surface of the fabric. If not removed the lint interferes with the drop placement of the inks thereby affecting the print quality.

Once the fabric is ready pre-treatment is done. The two most conventional and popular methods are “Dip & Nip Coating” & “Spray Coating”. In general, for standard-width fabrics, the Dip & Nip Coating method is used for padding followed by the dryer.

In this method, the fabric is dipped into padding liquor, and then excess liquor is squeezed out by pressure. For wider widths and some latest pre-treatment set-ups use the Spray Coating method to coat the surface of the fabric.

The dip & Nip method generally is suitable for medium & low GSM fabrics with pick-up ratios of 60-100% of fabric GSM. It needs more energy to dry the fabrics. However, it’s really easy to coat the fabric evenly with this method. The spraying method can handle a wide variety of fabrics.

Due to the lower utilization of padding chemicals, it’s easier to dry the fabrics. It’s also possible to apply function-specific or more concentrated pre-treatments on the surface of the fabric. That facilitates and overcomes the limitations such as coating thick fabrics. However, it needs a very precise approach to ensure even coating across the fabric surface.

There is a wide range of pretreatment chemicals available in the market. More than one ingredients are blended together to achieve the optimum performance with the pretreatment. In general, the right pretreatments have been found to improve wash and rub fastness by about half a point when compared to uncoated fabrics.

Most of the pretreatment additives are made of adhesion promoters, penetration enhancers, and polymerization catalysts. Together they work to facilitate curing and adhesion of the inks. Another class of pretreatment is also available which only enhances the appearance of the prints by arresting penetration of the inks.

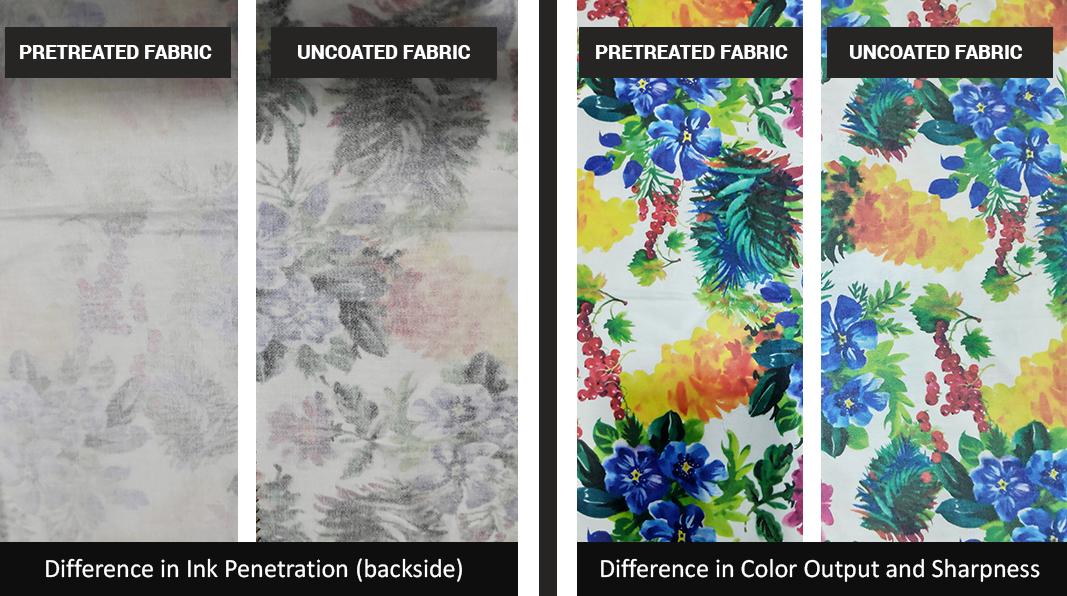

This class offers the advantage of economy for user applications where cost calculations are competitive. Pretreatment also provides a base for the ink to settle and improves the sharpness of prints. In the below image, the Difference in Ink Penetration on the Pretreated and Uncoated Fabric can be seen. Similarly, the pretreated Fabric appears to be more Vivid and sharp.

It is very important to find the right ratio of the pretreatment mix as per the nature of the fabric. Excess adhesion promoters may result in bright colors but poor wash and rub performance. Excess penetration enhancers will deliver good wash & rub fastness but faded or dull colors.

Pre-treatment and the ink combination also affect the fabric’s hand feel or texture. While all suppliers provide the standard recipe, it’s important to verify the performance before proceeding with bulk print jobs.

It not only ensures performance but also helps to optimize the print costs. Most of the pretreatment chemicals or ingredients by standard manufacturers are registered and compliant with various safety standards prevalent in the industry.

While it’s recommended to pretreat the fabrics, it’s something that is not always possible. For some fabrics where surface finish is critical or may coating process may result in changes in the feel of the fabric, pre-treatment should not be done. The lack of pre-treatment has to be compensated by using print settings to deposit a higher amount of the inks.

At Splashjet we offer a range of options for pre-treatment of fabrics that go along with our DuraJet DTex range of Digital Textile Pigment inks. Our team is ready to help you optimize the process and recipe for the best performance with optimum inputs. If you are interested to know more, reach us on our website – www.splashjet-ink.com