Sublimation printing is one of the most popular methods for Personalized or Custom digital printing. This article will give you a brief idea about the factors that can affect your sublimation transfer results and how you can prevent it. If you are not aware of sublimation printing and how it works, then you can read this article to understand the process.

However, if you already know about sublimation printing, then read this article completely to learn about getting the best results using sublimation printing. So let’s get started.

Factors that Impact Sublimation Printing Results

The following are the major factors that impact sublimation Printing Results:

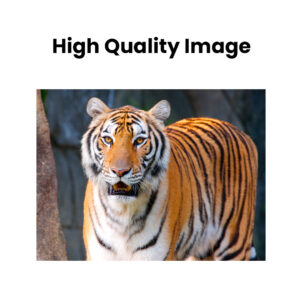

Poor-Quality Images

When you choose images downloaded from the internet, or shared via any social media platform the image resolution will be low as they might get compressed. Though the images appear good on screen, it doesn’t mean that they always have high resolution for high-quality prints. It may result in blurred or poor-quality prints. Thus, when printing, you’re likely to get poor-quality sublimation transfer.

Improper print settings

The color and print quality performance of a print varies considerably based on print settings. Color management settings of the software, eg. Photoshop, Coral Draw, etc. used for image editing also play a major role in this.

It is very important to use proper settings to get good results. Selecting the correct media type, print quality, and color mode are the important aspects.

Improper fabric selection / improperly coated sublimation substrate:

Sublimation transfer is not effective when you choose non-compatible sublimation blanks or an improperly coated sublimation substrate. In the custom printing and personalized gifting industry, if the fabric/blank is a non-polyester/non-polyester blend and the sublimating substrates don’t have compatible coatings, then you’re likely to get no sublimation transfer results.

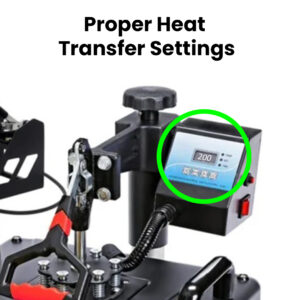

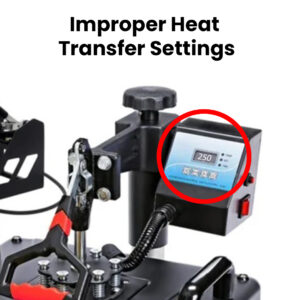

Improper heat transfer settings:

Improper heat transfer settings involve not choosing the right temperature, pressure, and time setting while printing. When you’re not able to maintain the proper pressure on the transfer area, it will lead to the sublimation dye migrating to the adjoining areas of the image resulting in poor transfers. The banding defects on your sublimation blanks can also result in poor-quality sublimation transfer.

How to overcome the above factors and achieve the best results for sublimation printing?

To achieve the best result following practices should be followed –

High-quality sublimation transfer or prints –

To get high-quality sublimation transfers, always choose high-contrast images with high resolution, otherwise edit them with a tool or software to enhance their color contrast before printing. Also, choosing a high-quality image setting will give you better print results which indirectly give you excellent sublimation transfers.

Tip – Make sure that the printer nozzles are performing well and are calibrated, before printing the image.

Proper printer settings –

To achieve high-quality prints, the generalized printer settings are as follows:

Go to Print Settings >> Paper Type >> Epson Matte >> Select Quality >> High >> Colour >> Select Additional Settings >> Mirror Image

Note: For Brother printers, the printer settings might vary.

Proper Fabric Selection / Properly coated sublimation substrate –

Material Selection is a crucial element when it comes to sublimation printing. Polyester or Polyblend fabrics (with at least 65% polyester) are used for customized sublimation printing. On the other hand, other substrates like Ceramic Mugs, Plates, Mobile Covers, Mouse pads, etc. should be sublimation-coated to offer high-quality print results.

Proper heat transfer settings –

You can Transfer sublimation ink according to your heat transfer equipment. The Standard settings for temperature are between 180°C to 200°C or 356°F to 392°F and the Transfer time needs to be between 40 to 120 Seconds as per your substrate and equipment. Following are the heat transfer settings for polyester blend fabrics and ceramic blanks. Below is the table that can help you identify the Standard Temperature and Time settings for the Sublimation printing.

Substrate

Press Time

Temperature

Tips/Comment (Optional)

Ceramic Mugs, Plates, etc.

90-180 Seconds 180°C - 190°C / 356°F - 374°F Heated material should be cooled properly to avoid thermal cracks. MDF Keychains, Photo-frames, Coasters 80-90 Seconds 180°C - 190°C / 356°F - 374°F Remove plastic coating. Product face-up with the transfer paper on top. Mobile Covers or Cases (3D Sublimation) 360-480 Seconds 185°C - 200°C / 365°F - 392°F 3D sublimation transfer. Mouse Pads 40-60 Seconds 185°C - 200°C / 365°F - 392°F Pre-press, lint roll to clean surface. White Polyester Fabric or Garment 40-60 Seconds 185°C - 200°C / 365°F - 392°F Transfer directly. Pre-press fabric for 3-5 seconds to eliminate moisture. Steel Bottles, Tumblers, etc (Sublimation Coated) 40-60 Seconds 185°C - 200°C / 365°F - 392°F Oven temperature and time will vary. Frosted Glassware (Sublimation Coated) 240-300 Seconds 180°C - 190°C / 356°F - 374°F Oven temperature and time will vary.

Conclusion:

In conclusion, we’ve discussed several factors that can impact sublimation printing and how to overcome them. Learning all these factors and experimenting with your printing can help you enhance the printing quality and achieve the best sublimation results.

If you are a sublimation business owner then it is going to help you a lot. If you are looking to start your own sublimation business then we recommend reading – Start Your Sublimation Business.