Inkjet printers have become an indispensable tool for both businesses and individuals, thanks to their exceptional printing capabilities that deliver high-quality results. However, at the heart of these printers lies a critical component known as the printhead. As you already know, the printhead’s role is paramount in ensuring the printer’s efficiency and durability. When the printhead malfunctions, it can lead to issues like blocked nozzles, subpar print quality, and the need for costly repairs. In this article, we will take a closer look at 12 primary reasons why inkjet printhead fails and outline proactive steps to avert such problems.

1. Dust and Environmental Pollution

One of the primary culprits behind printhead failures is dust and environmental pollution. When printers are used in dusty environments, particles suspended in the air can find their way into the ink system or ink containers. The outcome? These particles, which are often larger than 1 micron, can cause permanent nozzle clogging and damage that is challenging to remove through standard cleaning solutions. If you give your printer a cozy home, i.e. maintain a closed, temperature-controlled, and dust-free printing environment you can extend printhead life and optimize printer performance.

2. Using “Universal” Inks

Using inks that do not match the specifications of the printhead or universal inks can lead to various issues. The use of mismatched inks can cause printhead temperature to rise, resulting in ink drying within the nozzles. This can cause mist or spray damage to the head as well as the electronics. Additionally, some universal inks may contain salts or heavy metals that can damage printhead nozzles over time. How do we go about preventing this? It is best to use inks specifically recommended by the printer manufacturer to avoid compatibility issues and printhead damage.

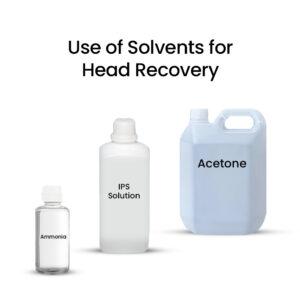

3. Use of Solvents for Head Recovery

It’s a common belief that giving your printheads a good cleaning with different solvents is the way to go. But here’s the thing: using different solvents to clean your printhead can end up doing more harm than good, even if things seem spick and span at first. Surprising, right? So, here’s the deal: using stuff like distilled water, your everyday drinking water (minerals and all), IPA (that’s only good for dye inks), and ammonia solutions – they’re a no-go. They might seem like a quick fix, but they can actually cause permanent damage. Instead of taking risks, go for cleaning solutions straight from the ink manufacturers. They’re like a safe and effective hug for your specific printhead type and inks. Trust them – they’ve got your printheads’ back!

4. Media Hit – Mechanical Impact

If the media roll or sheet collides with the printhead, it can cause mechanical and electrical failures to the printhead’s resistors, resulting in permanent damage. Paper with edge bends and curls can also impact printheads. Media that is too wet or elevated due to cockling is also undesirable. Proper handling of media and ensuring it doesn’t come into contact with the printhead is essential.

5. No Use for Long Time / No Maintenance

Inkjet printers are a bit like artists with liquid inks. If they take a long break from creating, i.e. if not used for an extended period, those inks can dry upright on the printhead’s nozzles. To prevent ink drying and clogging, it is recommended that you print and maintain the nozzles at least weekly. Regular maintenance can significantly extend the life of the printhead and ensure optimal printing performance.

6. Ink System Maintenance

The ink system in printers consists of various parts that contribute to the overall performance of the printhead. Ink filters/dampers, cleaning stations, and wiper blades play critical roles in maintaining the printhead’s health. Regularly replacing ink filters/dampers and cleaning the cleaning station and wiper blades are essential tasks to avoid nozzle clogging and printhead damage.

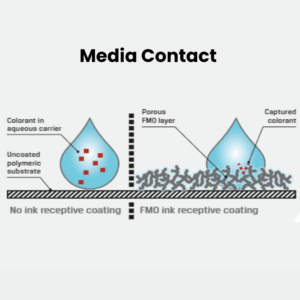

7. Media Contact

When costed media comes into contact with printhead nozzles, the coating on the media can react with the ink and lead to ink precipitation, resulting in clogged nozzles. Proper handling and avoidance of media touching the printhead are crucial to prevent such issues.

8. Working Conditions

You must know by now that the working conditions for the inks are an important aspect as well. Inks should be stored within the recommended temperature range (between 10°C and 35°C) to maintain their consistency. Extreme temperatures can cause ink thickening or reduced shelf life. The printer’s operating environment should also be maintained between 15°C and 25°C for reliable printhead performance. Additionally, controlling humidity, if possible, can improve ink drying speed, media performance, and electronics lifespan.

9. Air Turbulence and Radiation Heat

Air turbulence around the printhead can lead to faster ink drying and misting during printing, affecting print quality and potentially damaging electronics. Avoiding direct radiation exposure to the printhead from heated dryers or other sources is crucial to prevent damage.

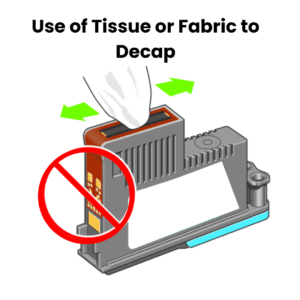

10. Use of Tissue or Fabric to Decap

When decapping the printhead, avoid using tissue or fabric that may contain bleaching chemicals or finishing agents. These chemicals can react with the ink and cause permanent nozzle clogging. What’s the smart move then? Let your printer take the lead here. Use the recommended purging or cleaning command from the printer to ensure safe printhead maintenance.

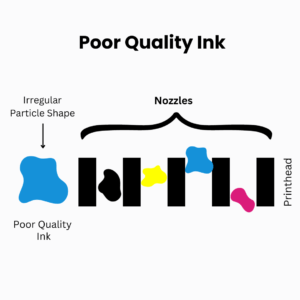

11. Poor Quality Inks

You are perhaps unaware of the fact that inks made with low-quality raw materials can contain salts and heavy metals that gradually damage printhead nozzles. Proper filtration and production environments are critical to ensure the quality and longevity of the ink. The correct approach here is to avoid repacking inks in dusty or unhygienic conditions to maintain ink integrity.

12. Mixing Different Types of Inks in the Ink System

Mixing different types of ink can lead to severe and permanent damage to printheads and the ink system. Inks of different types may react with each other, causing solids and liquids to separate and precipitate, leading to clogs. When switching from one type of ink to another, use flushing fluids recommended by the ink manufacturer to clean the entire ink system thoroughly.

Conclusion

By familiarizing yourself with these top 12 causes of inkjet printhead failures and taking the recommended preventive steps, you’re setting the stage for a longer printhead life, enhanced printer performance, and fewer worries about costly repairs. To ensure your printing operations run like a charm, keep these actions in your playbook: opt for the right inks, keep your workspace tidy and controlled, and stick to those regular maintenance routines. Your active involvement can make all the difference in the world of hassle-free, top-notch printing!