Dye Sublimation printing on woven polyester and knitted fabrics using a heat transfer printing process has established itself as a proven investment in recent years for the apparel and home decor industry.

What you all need for an effective Sublimation setup is a Good quality Heat press, Reliable, and affordable Dye Sublimation Ink, high release sublimation transfer paper, a high-speed Industrial sublimation printer, a few days of training and you can start your business in one of the fastest-growing industry called digital textile printing.

Limited investment in process machine, the flexibility of short-run production and even batch production process makes it very attractive even for the small investor.

How Does It Work?

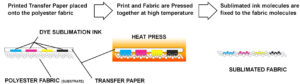

A special type of Ink called Dye sublimation ink is key to this heat transfer printing process. This ink has special characteristics of being able to transfer from paper to polyester fabric when applied to pressure and heat up to 180 to 200 deg C. Good quality sublimation paper ensures maximum color transfer retaining sharpness and details of designs. A reliable industrial sublimation printer is required to print your designs with this dye sublimation ink on sublimation paper. As a final step, heat transfer printing is achieved by a heat press which will do its job by applying uniform heat and pressure to sublimation paper and fabric. The printed fabric is now ready for the further process of stitching and finishing as per application.

How Does it happen?

Sublimation is a physical process through which a material changes its form from a solid to a gas state without first becoming a liquid. A special type of heat-sensitive dye called sublimation to disperse dyes is used to print designs onto special heat transfer paper. Upon heating at 200 deg C, the solid dye converts into a gas without ever becoming a liquid. At the same time, high temperature opens the pores of the polyester fibers and allows the gas to enter. When the temperature drops, the pores close, and the gas converts back to a solid-state resulting in transfer print from paper to fabric resulting into the sublimation printing process.

Lets List Advantages :

- Flexibility to set up small print setup

- Extraordinary vibrant print results

- No Hand or Feel to the printed fabric

- Excellent wash and fade-resistant transfers

- Relatively Fewer investment costs

- Fast return on Investment

- Non-polluting Industry – No special permission

- Suitable for Small rub production or even batch production

- Limited manpower requirement

- No Pre-treatment or post-treatment like coating or washing is required

- Fast Process enabling quick & large production

Challenges

While sublimation printing offers numerous advantages, it also comes with certain limitations that need to be addressed:

-

- Limited Fabric Compatibility: Sublimation works effectively only on specific synthetic fibers such as polyester, Nylon 66, polyvinyl, polyethylene, and fluoropolymers or their blends. It is not suitable for natural fabrics like cotton or jute.

- Substrate Color Restriction: This digital process is optimized for CMYK inks and requires a white or light-colored substrate to ensure accurate color reproduction. Printing on darker fabrics is not feasible.

- Color Fading After Printing: One common challenge is that sublimation ink colors may appear faded after printing. This can be due to factors such as incorrect temperature or pressure during heat transfer, suboptimal ink or media quality, or fabric composition that doesn’t fully absorb the dyes.

Looking for Quality Dye Sublimation Ink?

Over the last few years, many manufacturers are offering sublimation inks. At times it becomes difficult to understand quality parameters that define the quality of inks.

- Color Concentration – high dye content

- Consistent run ability – Print head specific ink formulation

- Purity Of dyestuff – long print head life

- Suitability to most heat transfer paper in the market.

- Stable Ink dispersion chemistry – long shelf life

Every printer and printhead has different demands from inks. Also, every sublimation transfer paper is unique and a wide range of variety of such papers are available in the market. Ranging from heavyweight coated paper to low weight non-coated/thinly coated papers, different users and different applications use different papers across the globe. Dye Sublimation Ink selection need all of the above considerations while selecting a proper grade or supplier for effective results. Splashjet’s sublimation ink offers excellent performance with the latest high-speed print heads. Be it Vivid colors, Clog free Nozzles, excellent wash fastness, and High release transfers, Splashjet Inks deliver value consistently.

Dye Sublimation Applications

The growth of dye-sublimation printing has been driven by the apparel and sportswear industry where the high-quality polyester fabric is widely used.

A wide range of apparel items including sportswear t-shirts, jackets, coats, kids wear, shirts, pants, and dresses are widely being printed with dye sublimation inks.

Also, sublimation printing is getting wide acceptance in the soft signage and display industry. Printed umbrellas, display banners, standees, and many more types of signage products are produced using a sublimation transfer process.

In addition to this gifting industry is flourishing with personalized printing concepts on various gift articles like mobile covers, Coated Mugs, mouse pads, caps, coated metals, wood, plastics, ceramic, leather, glass, stone and many more.

Conclusion

Thus, Sublimation heat transfer printing has evolved as the most preferred printing method for digital printing of textiles. Low investment and fast returns are making this an attractive opportunity across the world. Markets are growing not only in numbers but also new applications and concepts are helping this market to flourish.

Flexibility to startups with limited investment against any conventional printing process is a key factor driving this business. Availability of good quality equipment and consumables like dye sublimation inks and sublimation paper is also a key factor for cost-effective production and competitiveness.

Read – The Things You will Need to do to Start Your Own Sublimation Printing Business

This Post Has One Comment

Pingback: Textile Printing Inks - All About Types of Inks – Splashjet-lnk