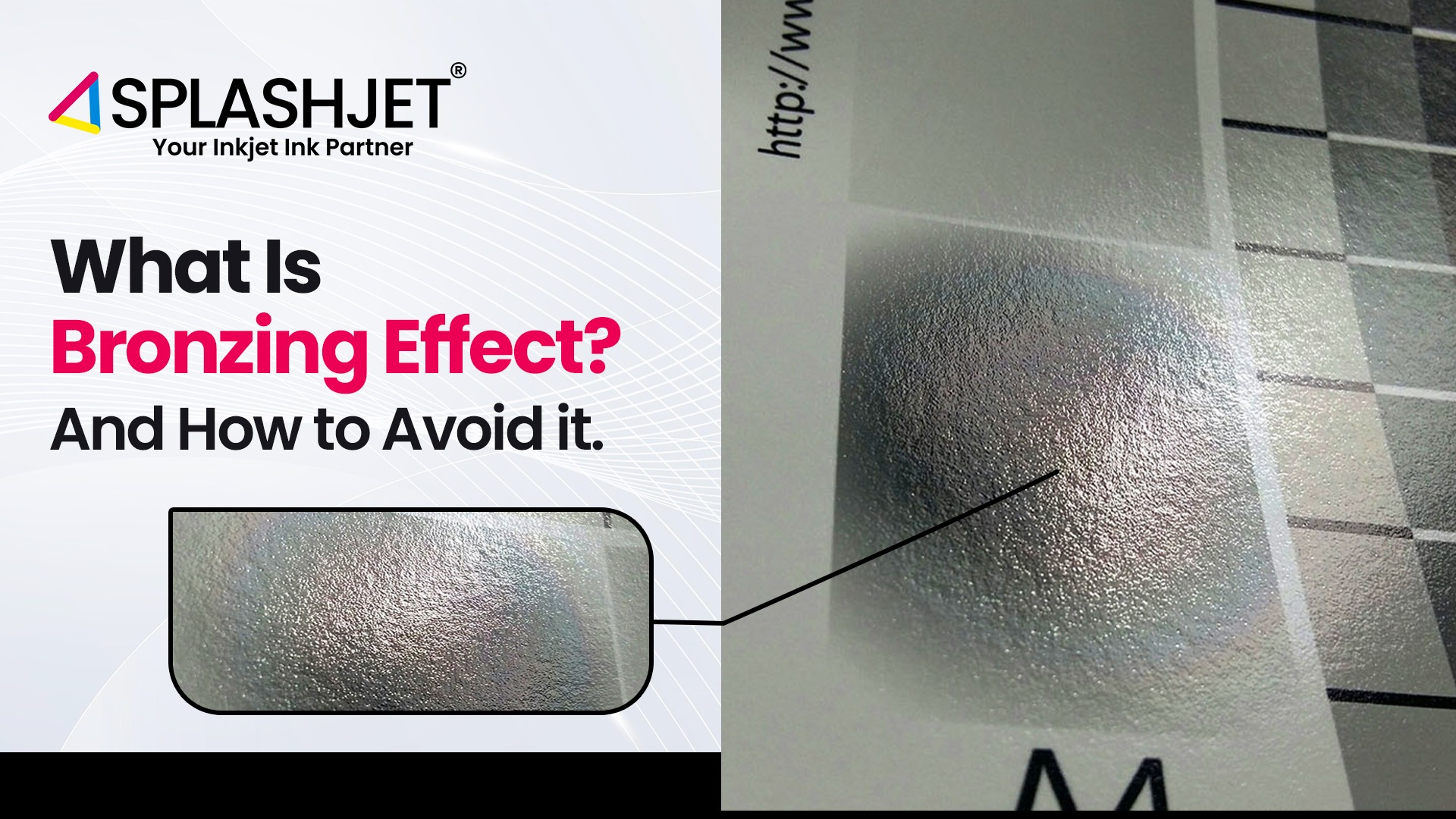

Have you ever noticed a different color or sheen on your prints when viewed from a certain angle under the light? If so, you’ve likely encountered a phenomenon known as bronzing.

Bronzing occurs when certain tones, especially gray and black, appear to have a metallic or colored sheen (a soft luster on the page)when viewed from an angle. This happens because the ink is not fully absorbed by the coating of the media and instead remains on the surface. As a result, light reflects differently, creating an unintended color shift or shine.

Role of Media Type in Bronzing

The bronzing effect doesn’t rely solely on the ink; it’s also heavily influenced by the type of paper used. Among the most commonly compared paper types are matte RC Glossy, and RC Satin papers. Each has distinct characteristics that affect how light interacts with the printed surface.

| Matte Paper | Glossy Paper | Matte Paper | RC Satin Paper |

|---|---|---|---|

| Surface Texture | Smooth and shiny | Rough and non-reflective | Smooth, semi-gloss surface with slight texture |

| Light Reflection | High specular reflection (light bounces straight back) | Scattered reflection (diffuses light in many directions) | Moderate reflection – soft sheen |

| Bronzing Visibility | High–sheen is easily seen under light | Low bronzing is barely noticeable | Low to Medium – reduced sheen |

| Ink Absorption | Minimal ink sits more on the surface | Higher–ink penetrates deeper into the paper | Balanced – ink is absorbed evenly. |

| Coating Impact | Coating enhances gloss, increasing bronzing | Coating absorbs light and ink, reducing gloss and bronzing | Resin & satin finish limit gloss while improving ink hold and drying |

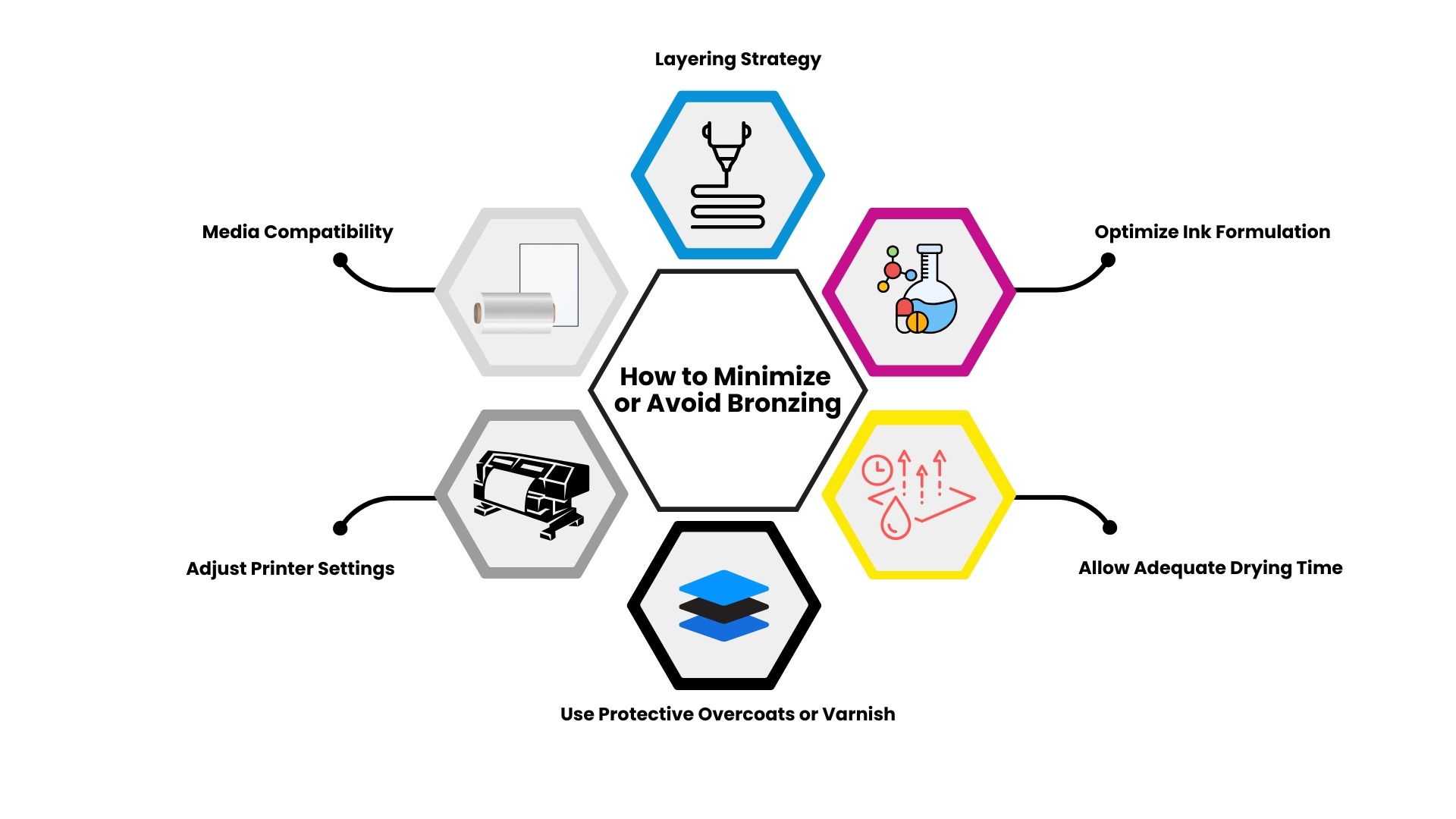

How to Minimize or Avoid Bronzing

We discussed what bronzing is, the technical parameters behind this phenomenon, right from ink to paper type. But this doesn’t solve your issues, so what are the best practices to avoid or minimize the bronzing effect? Let’s list them down one by one :

1. Media Compatibility

Use ink-compatible media (manufacturer-recommended glossy/matte paper). Ensures optimal absorption and coating chemistry for reduced surface reflection.

2. Optimize Ink Formulation

Using high-quality ink that is optimized for pigment dispersion and surface tension, such as Splashjet‘s. Reduces surface sitting and improves pigment alignment to minimize sheen.

3. Allow Adequate Drying Time

Leaving your prints to dry or cure for an adequate amount of time before handling or overcoating prevents smearing and ensures the pigments settle uniformly. Which ultimately reduces the possibility of bronzing.

4. Adjust Printer Settings

Choosing the appropriate print modes can help you reduce the print wastage, e.g., “photo” or “matte paper” mode, which results in Adjusted ink laydown, resolution, and drying parameters.

5. Use Protective Overcoats or Varnish

Applying Protective Overcoats or Varnish can effectively reduce bronzing by covering the ink surface. This replaces the ink-air interface with a more neutral, often matte coating, diminishing specular reflection.

6. Layering Strategy

Avoid over-inking and use multiple light passes instead of one heavy pass, which allows the ink to settle steadily, resulting in even pigment deposition and drying.

Conclusion

Bronzing may seem like a minor visual artifact, but in high-quality printing, even subtle surface irregularities can compromise the final output. Understanding the root cause can help you print more effortlessly and efficiently.

In the above article, we discussed what bronzing is, what the factors responsible for it are, whether the media plays a crucial role in it, and how we can minimize the bronzing Phenomenon. So that your prints become flawless from every angle.