DTF or Sublimation – Which One is Right for You? Choosing the right fabric printing method can make or break your business! With printing technology evolving rapidly, It’s difficult to choose between DTF (Direct-to-Film) and Sublimation printing. Each has unique strengths—DTF is perfect for small businesses and on-demand customization, while Sublimation shines in high-volume production with vibrant, long-lasting prints.

Understanding their differences is key to maximizing efficiency and profitability. In this article, we’ll break down both techniques to help you make the best choice for your business growth!

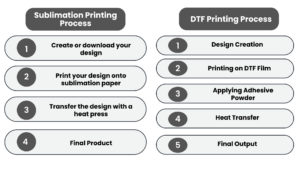

1. DTF Printing

Direct-to-film (DTF) printing is a process where a design is first printed onto a special film. An adhesive powder is then applied to the printed film to ensure the ink adheres properly. After curing the adhesive, the design is transferred onto the fabric using heat and pressure. DTF printing works well on various materials, including cotton, nylon, polyester, and treated silk, making it ideal for T-shirts, tote bags, hats, and other garments.

2. Sublimation Printing

Sublimation printing is a process that converts solid ink into gas without passing through a liquid state. This method transfers images from specially printed paper onto fabric using heat and pressure. Sublimation inks work best with polyester fabrics and coated surfaces, making them ideal for sportswear, swimwear, mugs, flags, and other promotional items.

Process difference:

3. Key Differences: DTF vs Sublimation

| Factors | Epson Ecotank L805 | Epson Ecotank L8050 |

|---|---|---|

| Ink Tank System | Separate CISS-like Tanks | In-build InkTanks |

| Printing Speed | Slower | Faster |

| Control Panel | Basic control panel | Basic control panel |

| Print Quality | Sharp and vibrant | Precise and detailed |

| Ink Efficient Printing | Yes | Yes |

| General Printing Costs | Low | Low |

| Max Print Resolution | 5760 x 1440 dpi | 5760 x 1440 dpi |

| Paper Handling | Versatile | Versatile |

4. Which One Should You Choose?

Choosing between DTF (Direct-to-Film) printing and sublimation printing depends on various factors, including business model, budget, and quality requirements. Both printing methods have their advantages, making them suitable for different applications.

- Types of fabric: Choosing the right fabric is key to achieving high-quality results. DTF printing works on almost any fabric, while sublimation is best suited for polyester blends.

- Size of order: Sublimation printing is ideal for high-volume projects, while DTF is perfect for on-demand and small-batch orders.

- Fabric color: Sublimation is best for light-colored fabrics, while DTF works well on dark fabrics.

- Print Size: Sublimation is suitable for all sizes of prints, whereas the DTF is not recommended for large printing sizes.

When choosing between the two, consider factors such as production volume, fabric compatibility, equipment cost, and overall business goals. If you require high-speed bulk production, sublimation might be the best fit. However, if you need flexibility and the ability to print on multiple fabric types, DTF printing is the better option.

Conclusion

Whether you choose sublimation printing or DTF printing, the most important factor is achieving high-quality results that meet customer expectations. Both methods offer unique advantages, and the right choice depends on your business needs, fabric compatibility, and production scale. While sublimation excels in vibrant, high-volume printing, DTF provides versatility across various materials. Ultimately, ensuring customer satisfaction while maintaining profitability is the key to a successful printing business.