In textile printing, Pigment inks combined with pretreatments are becoming a game changer. It not only offers unparalleled results but also an opening of a new horizon to make your fabric as you imagined in the world of textile printing. Because of this, Pretreatment has become an indispensable part of the pigment ecosystem.

If you are a textile printing business owner and you want to characterize your fabric in some or the other way pretreating your fabrics will definitely give you an edge to outshine, so here we will list down some of the characteristics why this combination is a gateway of new possibilities.

Let’s explore the dimensions that pigment ink and pretreatment are reaching.

1. Enhancing Ink Adhesion and Color Brilliance

The Pretreatment serves as a foundation for optimal ink adhesion, ensuring the pigments bind effectively to the fabric surface.

By uniformly coating the fabric with a pretreatment solution, you create a receptive surface that maximizes color brilliance and saturation.

The result? Prints that give stunning vibrancy, sharpness, and color accuracy that mesmerize both the eye and the touch.

2. Unleashing Versatility and Compatibility

Different fabrics possess diverse surface characteristics, porosity levels, and fiber compositions.

Applying the appropriate pretreatment ensures consistent ink absorption, minimizes bleeding, and allows for precise color reproduction across various fabric types.

From cotton to polyester and its blends, pretreatments enable high-quality printing on a wide range of textiles, including specialty fabrics.

3. Ensuring Durability and Wash Fastness

The true power of pretreatment shines when the textile undergoes various challenges including repeated washing and exposure to environmental elements.

Properly pretreating the fabric enhances the ink’s durability and wash fastness properties.

The pretreatment creates a strong adhesion, preventing the pigments from fading or washing out over time.

As a result, your printed textiles maintain their vivid colors, sharp details, and overall visual impact even after multiple wash cycles.

Industrial Innovation

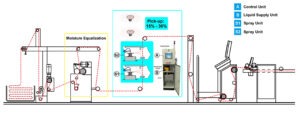

The Jet-able or Inline pretreatment has been around for a while now, this technology in textile printing allows pretreatment to be applied directly through the printer in a single step.

Instead of the traditional method, this method does not need a separate step to prepare the fabric, this method applies the pretreatment right as the fabric is printed. This makes the printing process faster & more consistent and reduces the need for extra handling.

This pretreatments and pigment inks when combined with industrial innovations embrace the synergy between innovation and demand, which is a key to staying ahead in the industry.

As an efficient and eco-friendly option, jet-able pretreatment is becoming popular in textile printing to save time and reduce waste.

Conclusion :-

The Pretreatment has revolutionized the digital textile printing industry. The Pretreatment gives a foundation for the way you want to characterize your textile whether it is for superior ink adhesion, or ensuring colors are brilliant and sharp even after repeated washing. It gives you the edge to enhance the compatibility of pigment inks with a wide range of fabrics. Additionally, innovations like jet-able pretreatment streamline the process, offering efficiency, consistency, and eco-friendliness.